Making the right choice between spring set and permanent magnet brakes can impact safety, durability, maintenance and performance

Power-off brakes are designed to hold or stop motion in the absence of power. Given the safety ramifications of keeping a system locked in place until it is powered up, motion control system designers tend to specify power-off brakes. There are two different fail-safe brake technologies: one uses compression springs to hold its load in place; the other uses permanent magnets. Each has specific strengths and weaknesses, and knowing the difference can impact safety, durability, cost and performance.

Technical characteristics of spring set brakes

In spring set architectures (Figure 1), compression springs (1) apply the braking force. When the power is off, the force from the springs pushes the non-rotating armature plate (2) into a rotor (3). The rotor hub fits a splined or hex-shape shaft, connecting the load. In power-off mode, springs hold the rotor keeping its connected clamped load. The advanced friction material (4) on the rotor maintains its torque.

Energizing the coil (6) produces the electromagnetic magnetic force pulling the armature from the rotor (5), freeing it to turn. Once operating, keeping the springs compressed requires only one-quarter of the initial voltage. If that voltage is removed, the spring decompresses and pushes the armature plate back against on the rotor, once again producing the friction to bring the load to a stop or holding it in place.

Technical characteristics of permanent magnet brakes

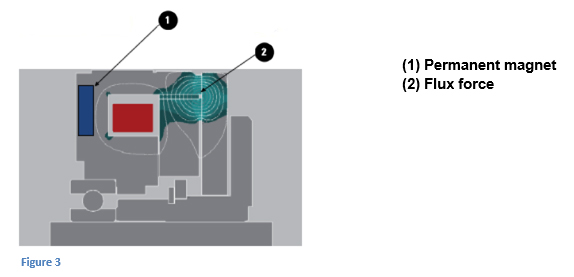

In normal power-off mode, the permanent magnet in the assembly (1) creates an attractive force on the armature assembly (2), which is attached to the load shaft by means of screws or pins, hence stopping or holding the load.

Energizing the coil (Figure 4) negates the natural magnetic field, reducing torque to zero, freeing the rotor and connected load to move (Figure 3). When the power is removed, the natural magnetic force takes over again, attracting the armature and holding the load in place. Because this magnetic force attracts the metal components, this is called “direct acting,” as compared with the pushing mechanism of spring set brakes, which is known as “reverse acting.”

Maximum performance of the direct acting designs requires metal-on-metal contact between the armature and the rotor. This eliminates backlash while the brakes are locked on. Direct action is efficient when delivering higher torque within a small footprint. It also enables higher-speed action with the brakes locking on or off at rapid intervals.

Achieving such advantages requires a steady, consistent supply of current. The brakes release over a narrow window, usually plus or minus 10% of the applied voltage (Figure 4). Outside that window, they can reapply.

This narrow range makes permanent magnet brakes sensitive to variations in current, making voltage regulators essential. Because the effect is attained by reversing polarity, reversing the prongs of a contact plug, for example, will interfere with the action, which is why matching red and black leads on power cables is critical to performance.

Because temperature fluctuations impact current flow, permanent magnet devices require operation in controlled temperatures. Even then, the metal-to-metal contact makes them highly sensitive to oxidation, which can reduce torque. If, for example, 10 inch-pounds of torque is required to hold a load, oxidation could reduce holding power to 8 inch-pounds over periods of inaction, even over the course of a weekend, requiring the need to burnish to regain the torque.

Applications

Technically, spring set and permanent magnet designs can perform the same basic function. Spring set brakes have advantages in the applications where machine safety, maintainability, dynamic stopping or costs are drivers. Permanent magnet brakes are favored where zero backlash, smaller footprint, speed or rapid cycling is needed.

Machine safety.

New spring set and permanent magnet technologies provide comparable braking performance and are safer than power-on brakes. But with wear, air gaps form between the components that can contribute to failure of both types of brakes. The higher the potential for personal or equipment damage in the event of a brake failure, the more advantageous the spring set designs become.

Dynamic stopping.

Spring set brakes are specified to stop and hold a load in place once stopped. These differ from permanent magnets, which are typically used to only hold the load in place as the metal-on metal-contact would wear even faster if applied for stopping.

High tolerance of voltage variability.

When consistent voltage is needed, spring set brakes again are preferred. The small window required for the electromagnetic force to counter the natural magnet makes permanent brakes highly unreliable amid fluctuating temperatures, electromagnetic interference or other forces that might alter the magnetic field or impact voltage levels. Using permanent magnet brakes in highly variable temperatures, for example, could cause them to brake or reapply at undesirable times.

Manual Control.

Spring set brakes also make it possible to implement a manual release, utilizing a lever or other mechanism to decompress the springs that are pushing the armature against the rotor. Releasing the hold of a permanent magnet, however, requires electrical energy. Manual release can be valuable for maintenance or in applications, including medical or factory automation equipment.

Maintainability and durability.

Spring set brakes also require less maintenance than permanent magnet brakes. The simpler design and advanced friction material means that they will wear less, run quieter and last longer, all of which contribute to a lower cost of operation and ownership. The metal-on-metal contact required for permanent brakes contributes more wear and tear, more particulates in the process and noisier operation, resulting in higher maintenance time and expense and shorter life.

Price. All other factors being equal or comparable, spring set devices typically will win out on price. They cost less than permanent magnet brakes because they don’t have the baseline cost of a magnet composed of rare earth metals, nor do they require as much complex, precision machine tooling. Price is especially critical in high-volume applications such as semiconductor pick and place and automotive applications. Permanent magnets are seldom found in high-volume applications because there is virtually no economy of scale in the cost of the magnets.

Where permanent magnets have advantages

Zero backlash.

One significant advantage of permanent magnet brakes over spring set designs is the fact that when they are holding, there is no play (near zero backlash) because of the armature/diaphragm/hub configuration. The spring set brake rotor-to-hub fit and armature-to-spacer clearance contribute to backlash when the rotor is being held.

Consider, for example a medical application where a doctor is performing eye surgery with a five-foot-long robotic arm. If the power goes off, the surgeon needs the arm to be in the exact same spot it was when the power went down. Even one degree of backlash multiplied by length of the arm would introduce an unsafe level of precision.

However, if the permanent magnet brake fails completely while in operation, it can introduce safety concerns of a different sort. This is why braking systems intended for such application are designed with extra care and precision and why it is critical to monitor them closely and frequently for early signs of wear.

Small footprint.

Because electromagnetic force does most of the work in applying the magnetic attractions, permanent magnets operate more efficiently with smaller components. As such, they need less space to operate and can be deployed in tighter quarters. This is increasingly important in medical device applications such as X-ray and mammography scanners as well as in static holding applications.

Speed and rapid cycling

Permanent magnets have an air gap between the output hub assembly and the magnet. With nothing contacting it, the output hub assembly can rotate at the speed the motor can achieve. Spring set brakes, on the other hand, have more moving parts, limiting RPM. Balancing spring set systems can increase the speed potential - but at a cost.

Managing the trade offs

From a performance standpoint, a third of all applications may be better served by spring set, a third by permanent magnet and a third by either.

Spring set brakes would be specified for an airline trim application, for example, as the permanent magnet would not operate effectively in the extreme physical conditions a plane might encounter. By contrast, a permanent magnet brake would be specified for medical devices, in which zero backlash is desirable, and voltage is more controllable.

Where either spring set or permanent magnet would provide comparable performance, the choice often comes down to price and availability. For many engineers, the safest and most effective alternative is the one they know.