The United States has about 160,000 miles of operational railroads, mostly composed of 39-foot rail segments welded end to end. Unless these connections and the rail surfaces are perfectly smooth, the rails could wear prematurely, affecting the comfort of the ride, impacting safety and increasing maintenance costs. To avoid such problems, railway maintenance workers use massive track grinders, guided by precision electric linear actuators.

How a rail grinder works

Railroad track grinders remove irregularities and restore the shape of worn railroad tracks, enhancing their surface smoothness. Their core component is a grinding wheel that contacts the rail as the grinder self-propels along the tracks. As it does, the grinding wheels rotate at high speeds to abrade corrugation, surface defects, fatigue cracks and other imperfections from the rail surface.

To maintain optimal contact between the wheel and the track, sensors mounted on the equipment frame scan the tracks for variations and send their readings to a control unit. The control unit then signals electric linear actuators to adjust grinding pressure based on variations in wear level.

Going electric

Traditionally, rail grinder manufacturers used hydraulic cylinders to provide these adjustments, primarily because of the high force needed and high duty cycle. But as rail ridership increased and with it the wear on the rail lines, at least one major, global rail grinder manufacturer has concluded that hydraulic cylinders did not have enough accuracy or stability to meet their expanding needs.

After extensive searching, they concluded that electric actuators could handle their loads with higher accuracy and greater stability. Electric actuators allow operators to adjust the grinding intensity and angle to match the contours of the track. Such precision is crucial for matching rail grinding to the correct profile for maximum safety and efficiency.

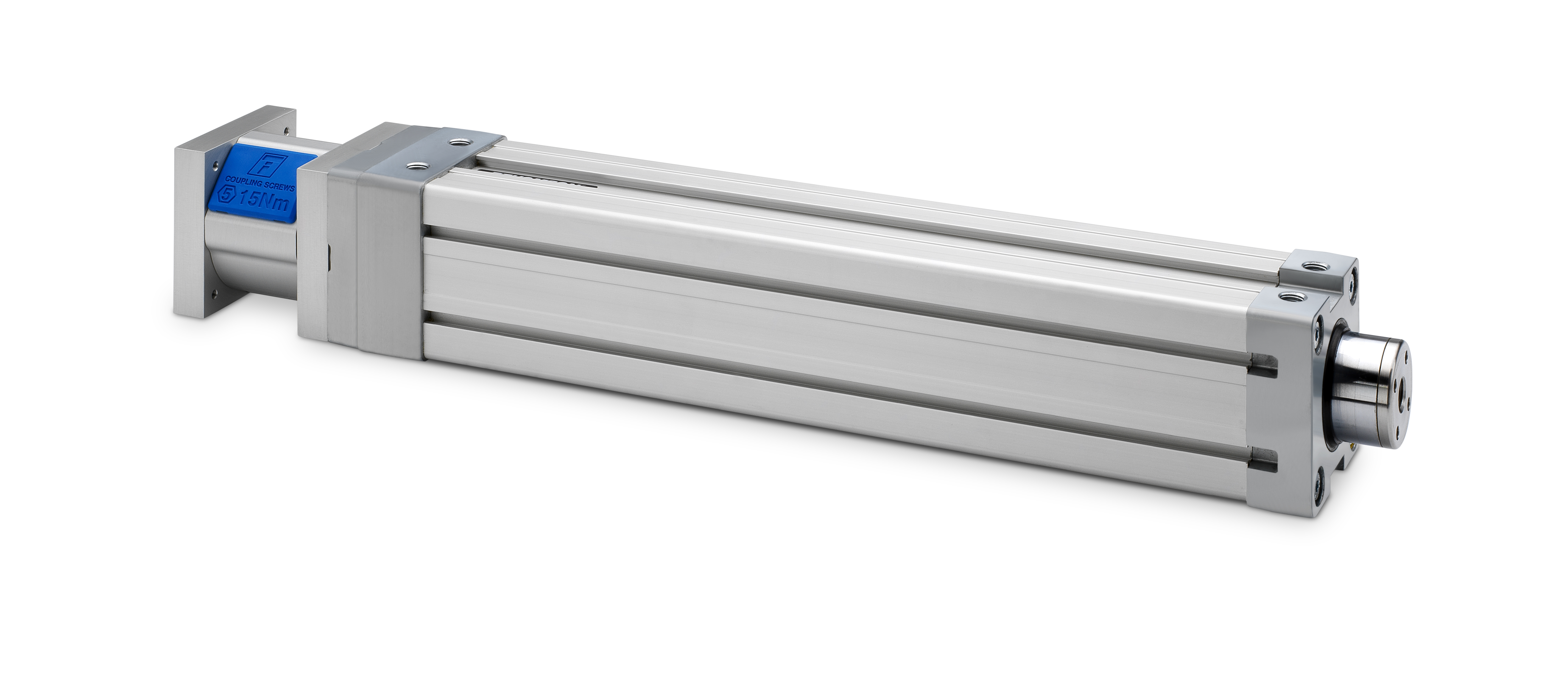

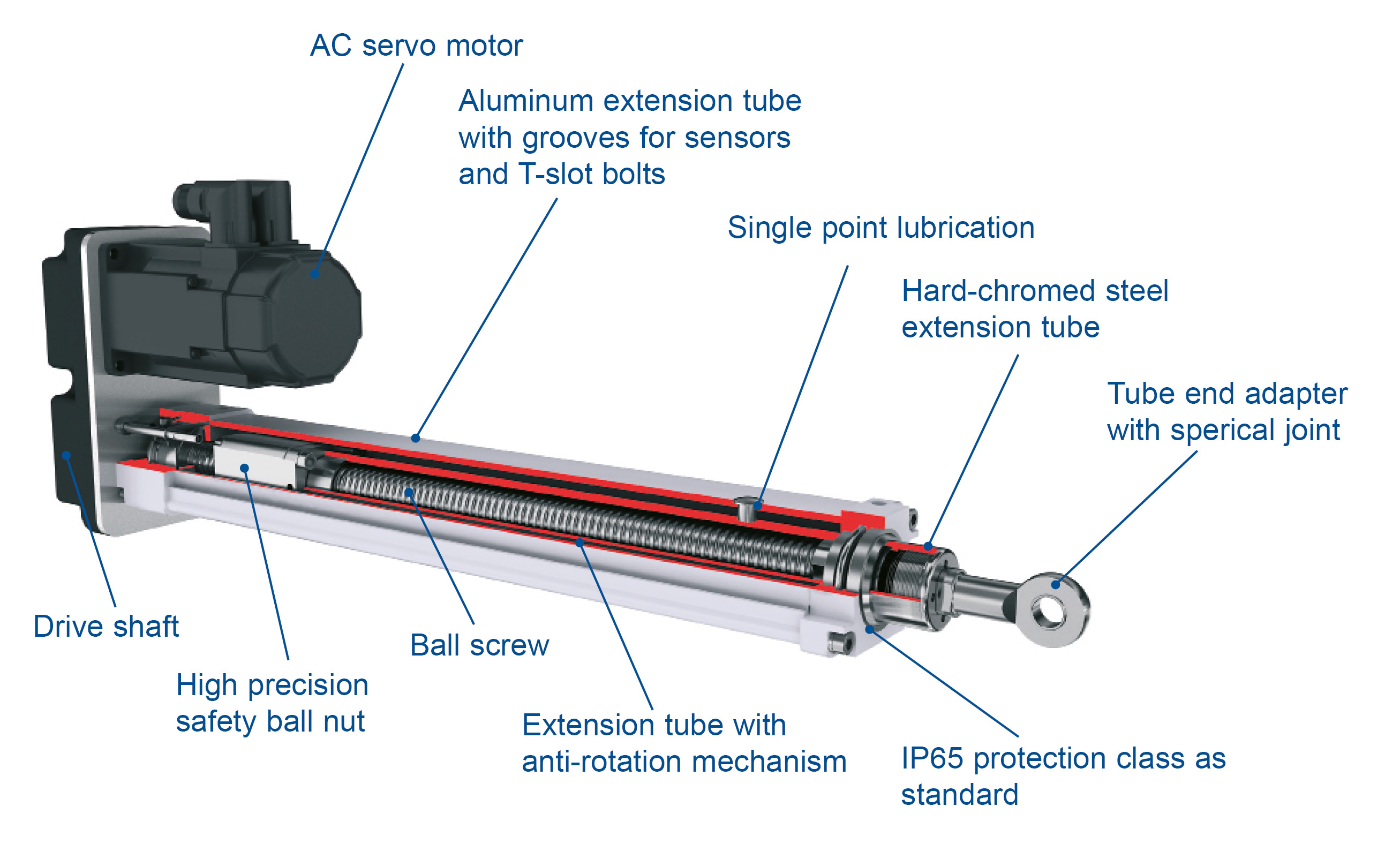

Possessing many of the same unique design characteristics that made hydraulic and pneumatic cylinders popular, electric actuators such as the Thomson T130 (pictured) benefit from cleaner, simpler and more energy efficient power transmission. They are also much easier to integrate with modern programmable controls, have greater accuracy and are less noisy.

After evaluating the offerings of several electric actuator vendors, the rail company chose to partner with Thomson, a leading provider of linear motion products. With the help of the Thomson online configuration tool and their engineers, they concluded that the T130 electric precision linear actuator would best meet their overall requirements for load, accuracy, stability and controllability.

Getting the thrust

Thomson has designed its T series precision linear actuators for applications requiring powerful performance over a long lifetime and thus, they are ideal replacements for cumbersome hydraulic cylinders. The rail grinding application required two tons of thrust, which, with its six-ton capability, the T130 met with ease.

Achieving accuracy

Thomson T130 precision linear actuators offer positional repeatability of 0.05 mm, which is higher than what is possible with hydraulic cylinders. With such high accuracy, the OEM can target grinding more specifically without introducing unnecessary wear. The result is smooth motion with minimal impact on life and durability.

Enabling stability

Loosened by aging, the seals of hydraulic cylinders wear out and begin to rotate. Because hydraulic cylinders are optimized for linear, and not rotational, loads, cylinder seal wear disturbs the alignment between the actuator piston rod and the grinding wheel, leading to binding or jamming of the piston and wobbling of the grinding wheel. The Thomson T130 actuator eliminates rotational problems with designed-in anti-rotation functionality. It uses an internal square guide rail nut, which prevents the extension tube from rotating if it is not attached to any load.

Smarter operation

In addition to exceeding requirements for load, accuracy and stability, the T130 has shown many other advantages for rail grinding. Embedded feedback from the servo motor enables participation in automation schemes, which could extend operation without operator intervention. In addition to storing and forwarding height measurements, it also provides position feedback to the actuator shaft, making it even easier to program and adjust. The sensors also collect and communicate data on wheel wear rate, rail condition and grind quality, all of which could drive further height and pressure adjustments or preventative maintenance.

Thomson has invested significant expertise and development in simple, but high-performance, precision linear actuators. IP65 protection, a robust design and the use of high-quality components make them suitable for usage in harsh environments.

Simpler and cleaner

Where hydraulic cylinders require fluid reservoirs, pumping and piping, electric actuators are plug-and-play, needing only a power and data cable. As opposed to fluid leaks and constant maintenance, electric actuators are clean and virtually maintenance-free, only requiring some lubrication. This extends the life of the rail grinder and reduces the need for costly replacements.

The right touch

With about 13 percent of the world’s 1.4 million miles of railroads, the United States has more miles of track than any other country. Only a small fraction of its railroad are high speed, exceeding 150 mph. This is expanding slowly but doesn’t impact the contact between the train wheels. The smoother that contact, the better it will be for riders as well as rail operators. Electric actuators will play a key role in optimizing the performance of the rail grinders, which will remain essential for quality rail travel.