When designing for linear motion systems, the initial decision between round and square rail can significantly impact cost, performance and durability. Square rail, which is typically the more expensive option, has a higher load capacity and tighter accuracy. Round rail offers distinct cost and reliability advantages for certain applications, but maximizing those advantages depends on specifying the right bearing to minimize friction in each application. Designers must often choose between plain bearings, often called bushings, and ball bearings. And within each type, they will have more options that impact price, performance, maintainability and durability. Understanding these options early in the design cycle will optimize the performance and cost of the linear motion application.

Plain and simple

Because plain bearings have no balls or other rolling elements, they are the least expensive to manufacture and thus cost less. They also outperform assemblies with rolling elements in terms of smoothness and quietness, and because they have fewer moving parts, they are less susceptible to dust and dirt.

Plain bearings with elastomer liners amplify these benefits. They are available with high-performance, bearing-grade materials applied to aluminum or other substrates to provide good load capacity (20% of that of a ball bearing) and a reasonably low friction coefficient, typically between 0.05 to 0.25.

Since the contact area of a plain bearing is distributed over a large area, plain bearings can also be used with unhardened round shafting, giving designers more flexibility to choose materials that address other design requirements such as corrosion protection or weight.

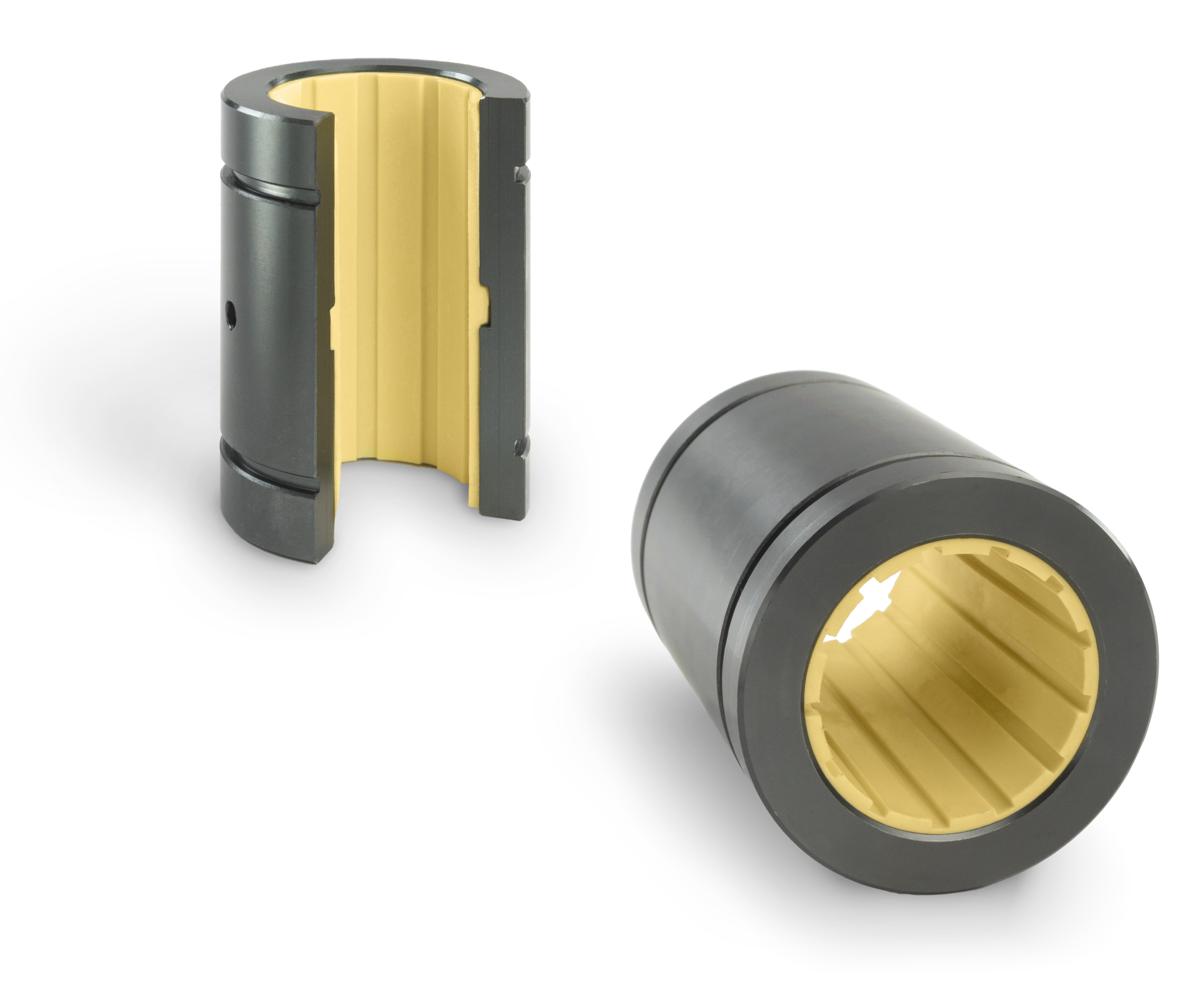

Some manufacturers make plain bearings from self-lubricating polymers that minimize the need for maintenance. (Figure 1)

Figure 1: With no balls or rolling elements as part of their construction, plain bearings such as the recently launched Thomson polymer bushings provide a smooth, quiet and economical option for light-load linear motion applications.

The cost savings and smooth operation of plain bearings, however, come at the cost of load handling, precision and speed. They are best for applications in which alignment and moment load are non-critical or those that require shafting that is incompatible with traditional Ball Bushings® such as aluminum or 316 stainless steel. Plain bearings typically handle static loads up to 11,000 lbf, and dynamic loads up to 2023 lbf, and speeds of up to 100 fpm. When those parameters are met, plain bearings -- especially those using polymers -- are beneficial in both clean and harsh environments. Primary applications involving light loads, lower speed and precision are found in packaging, factory automation, robotics, health and fitness, woodworking, food and beverage, and vending. Applications that might also involve ultra-clean, toxic or harsh environments include semiconductor production, medical automation and food production.

Scaling up

Applications requiring higher load handling, speed or precision will need bearings with internal rolling elements. The type of bearing specified will vary according to the number of balls used, directly impacting the allowable load and speed.

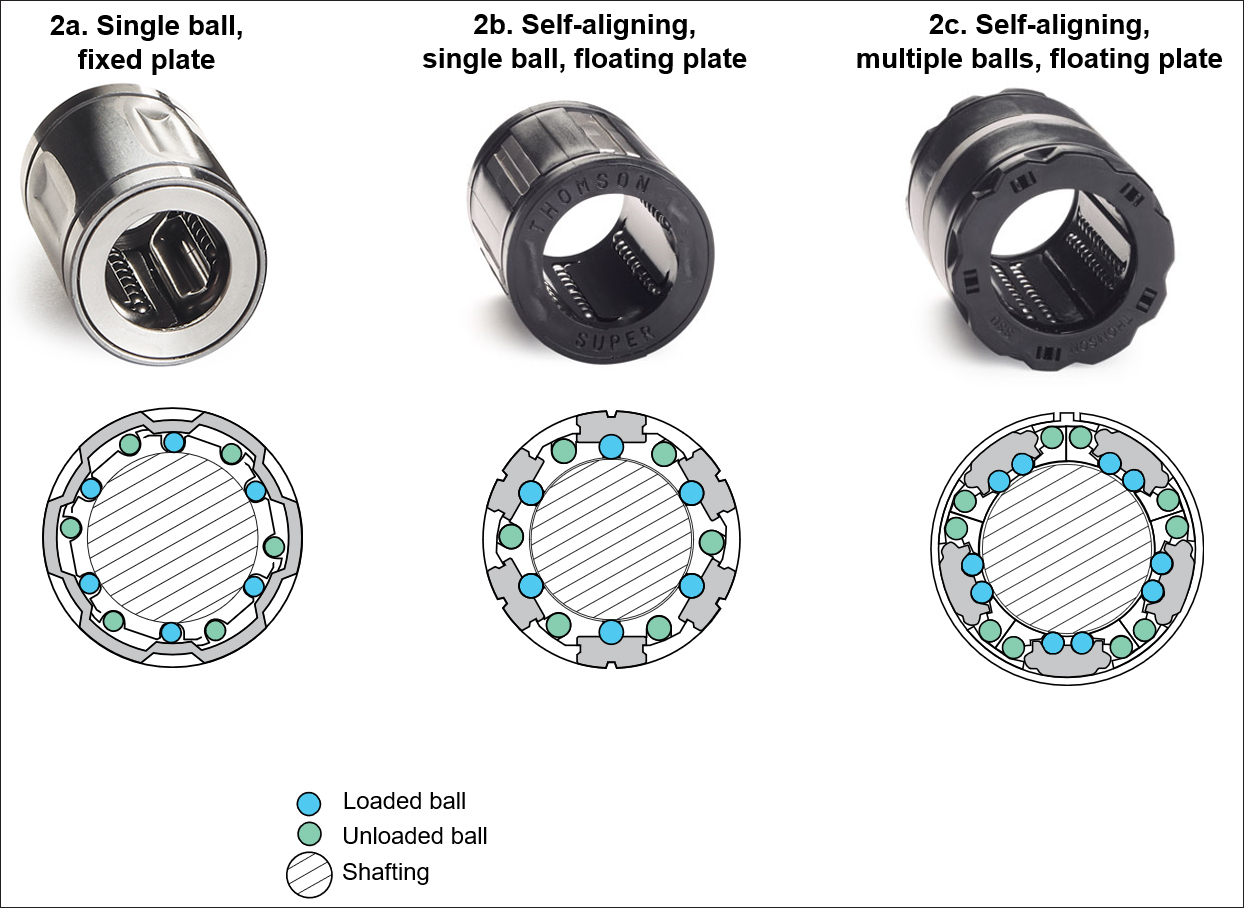

The precision steel design (Figure 2a) uses hardened steel linear ball bearings, which have point-to-point contact on a fixed point. This enables the handling of dynamic loads up to 5000 lbf and diameters from 0.25 to 4 inches.

The next performance level up embeds a single ball track in a conforming groove on a floating plate. (Figure 2b) This bearing has a low coefficient of friction and can triple the load handling capability over the fixed plate and increases bearing life up to 27 times longer than precision bearings. This configuration is optimal for rail 0.19 to 2 inches in diameter and dynamic loads up to 3000 lbf.

The more load-bearing balls in the load zone, the greater the load handling and durability. Deploying two ball tracks in a conforming floating track, for example, can increase the load capacity six times and bearing life 216 times over the precision bearing. (Figure 2c) This configuration is also optimal for rail 0.5 to 1.5 inches in diameter and dynamic loads up to 3880 lbf.

Figure 2: While all three linear bearings pictured use recirculating balls, their difference lies in that 2a employs a hardened sleeve that has a bearing surface ground into it, whereas 2b and 2c utilize floating bearing plates.

Self-aligning bearings extend life

When high load handling, speed and precision are high priorities, a self-aligning bearing can maintain a low coefficient of friction while maximizing bearing life. Some manufacturers accomplish this by designing the bearing plate so that the radius of its outer surface is smaller than that of the inside radius of the hardened precision ring. This allows the bearing plate to roll against the ring, evenly distributing the load on each of its two ball tracks. The bearing designs also allow the bearing plates to rock 0.5° about the hardened precision ring to ensure smooth ball entry and exit in the load-carrying zone, and optimum ball loading from end to end.

This self-aligning structure compensates for the torsional misalignment that might result from inaccuracies in base machining or machine deflection, with little increase in stress to the bearing components. Once a self-aligning bearing is mounted in an adjustable housing, designers can achieve a selected preload. The bearing design allows the bearing plates to move radially, which provides the ability to achieve close bearing/linear race fit-ups for high-precision applications.

Furthermore, although ball bearings are not necessarily as environmentally resistant as polymer plain bearings, certain actions can be taken to protect their high load handling and durability in corrosive environments. This includes specifying stainless steel, nylon or nylon-coated rolling elements in corrosive environments.

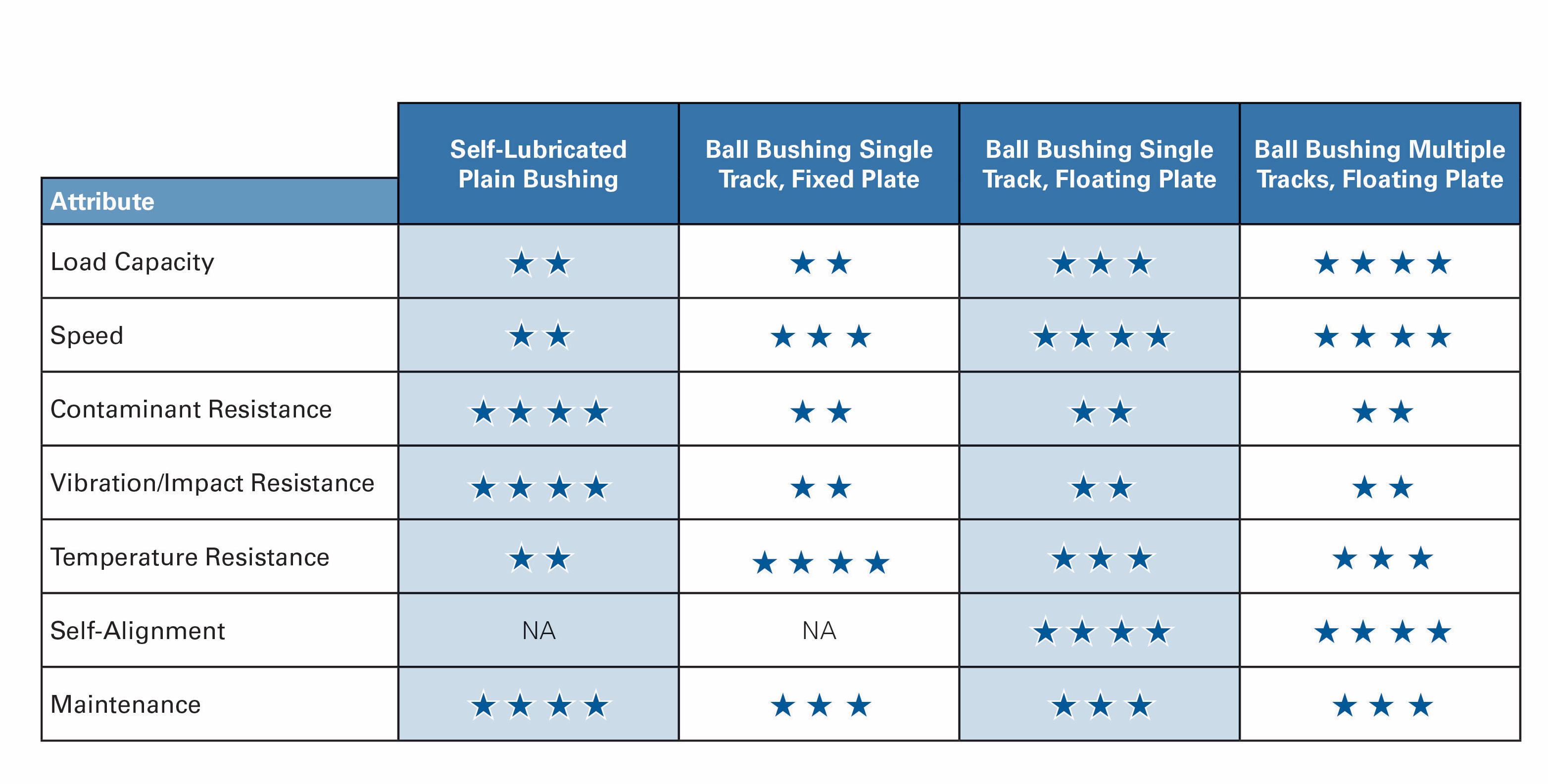

Choosing the right linear bearing can be a make or break decision. Based on your application’s requirements, the table above can help you determine an ideal solution.

In closing

If applications requiring low cost, smooth and quiet operation, or reliable performance in corrosive environments are more critical to your operation than high load handling, precision or speed, you should consider a plain bearing. If your shafting requirements are incompatible with traditional ball bearing materials such as aluminum or 316 stainless steel, polymer materials should be considered. If durability and maintainability are most important to your design, self-lubricating plain bearings would best suit your needs.

Otherwise, you will need a ball bearing, in which price, precision and load handling will vary depending upon the number of balls loaded, whether the ball track is fixed or floating, or whether the assembly is self-aligning. We have presented general guides on bearing selection, but this, of course, will vary according to your application’s requirements. Resources such as the LinearMotioneering® sizing and selection tools on the Thomson Industries website (www.thomsonlinear.com) can help you optimize bearing selection for your round rail applications.