Smart machines start with smart components: A closer look at electric linear actuators

Chad Carlberg, Thomson Industries

Max Miller, Motion Industries

A once-simple electric linear actuator that extends and retracts, while being controlled with a double pole, double throw (DPDT) switch, can now easily become part of a larger, interconnected system. No matter how mundane the actuator’s task, such as closing a safety gate, it can function as part of the overall machine function connected to a master brain. There is a need to know if the gate is open or closed without looking, or if the actuator is near the end of its life. The actuator’s control may need to signal other processes to start or stop, to sound alarms or even shut down the plant. And it needs to handle all of these tasks with Six Sigma reliability.

To capture the speed, load, position, direction, number of cycles, temperature, voltage, and current of an actuator would require a host of sensors, meters, counters, etc. However, each of these components will eventually fail and result in machine downtime. Enter the smart electric linear actuator. Manufacturers have answered the need for a maintenance-friendly, reliable and easy-to-install actuator. The microprocessor-based printed circuit board built into these actuators’ housings has only a few, simple connections that make the smart actuator easy to configure for many applications without the need for additional wiring.

Comparison to hydraulics/pneumatics

Increasingly, machine designers are replacing pneumatic and hydraulic cylinders with electric linear actuators, which provide more energy-efficient, cleaner and maintenance-free operation. In complex applications, electric linear actuators provide engineers with complete control over the motion profile. As a result of the increased controllability, the need for changeover when switching from one product to another is therefore eliminated.

In contrast to pneumatic and hydraulics, electric linear actuators can also provide considerable energy savings in the majority of applications as they only use power when needed. With easier control, lower energy costs, less noise and reduced maintenance time, electric linear actuators offer highly energy-efficient solutions and can better interact with systems for condition monitoring and predictive maintenance.

A key consideration for machine designers is to ensure the ‘right’ linear motion system is selected. Today, many companies that manufacture electromechanical actuators offer online tools that enable system designers to accurately size and select linear motion systems and other components optimized for their application needs.

What to watch for

Smart electric linear actuators are maintenance-free. The enclosure protects the internal components from harsh, dirty and wet environments, and the rod is corrosion-proof. The gearing and screw are lubricated for life. Of course, nothing is foolproof. Overload, misalignment and misapplication will result in failure. Overload will result in increased current and heat. The smart actuator will protect itself, but continued overload will reduce the life of the motor.

Smart electric linear actuators are built for straight-line thrust; the moving load must be guided. Side loads or misalignment of the rod will result in overload and could eventually bend the screw causing a catastrophic failure. Finally, linear actuators are designed for intermittent duty cycle applications. The load, stroke and speed will determine the duty cycle, usually 25% at full load. When production asks to speed the machine up and exceeds the duty cycle, the smart actuator will protect itself, cause nuisance tripping, resulting in a shorter life. However, when replacing a linear actuator, the time and cost required are minimal. Rod-extending smart linear actuators are available in AC or DC voltage with available quick connects for easy wiring. The mechanical installation could be clevis pin to clevis pin, trunnion, foot mount or flange mount.

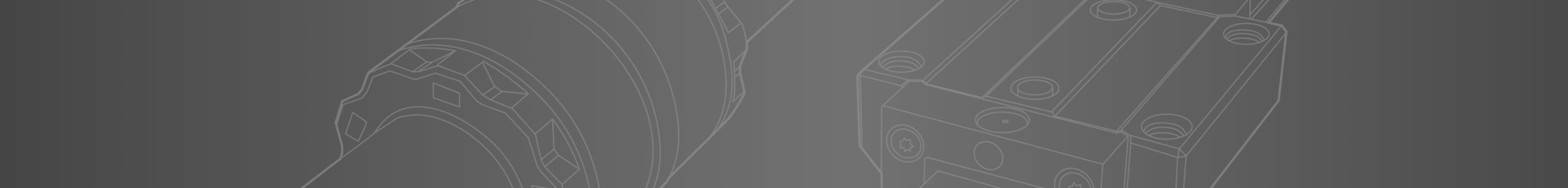

Image 1: Typical CAN bus network architecture. With just two wires for power (orange line) and two for network communications (Blue Line), smart actuators provide efficient, compact communications with each other and other devices (green box). (Image courtesy of Thomson Industries, Inc.)

Condition monitoring boosts plant intelligence

Smart actuators help OEM designers build smarter machines, and a contributing factor are the benefits of using integrated bus technology (Image 1). This allows design engineers to control the speed, position and current trip point of axes while receiving critical diagnostic data that can be used to optimize the performance of each device. The system will monitor the status of each device and share the information with machine operators, maintenance personnel, production managers and even other devices within the machine process. Programming operations, collecting data and condition monitoring in real time is what makes a factory smart.

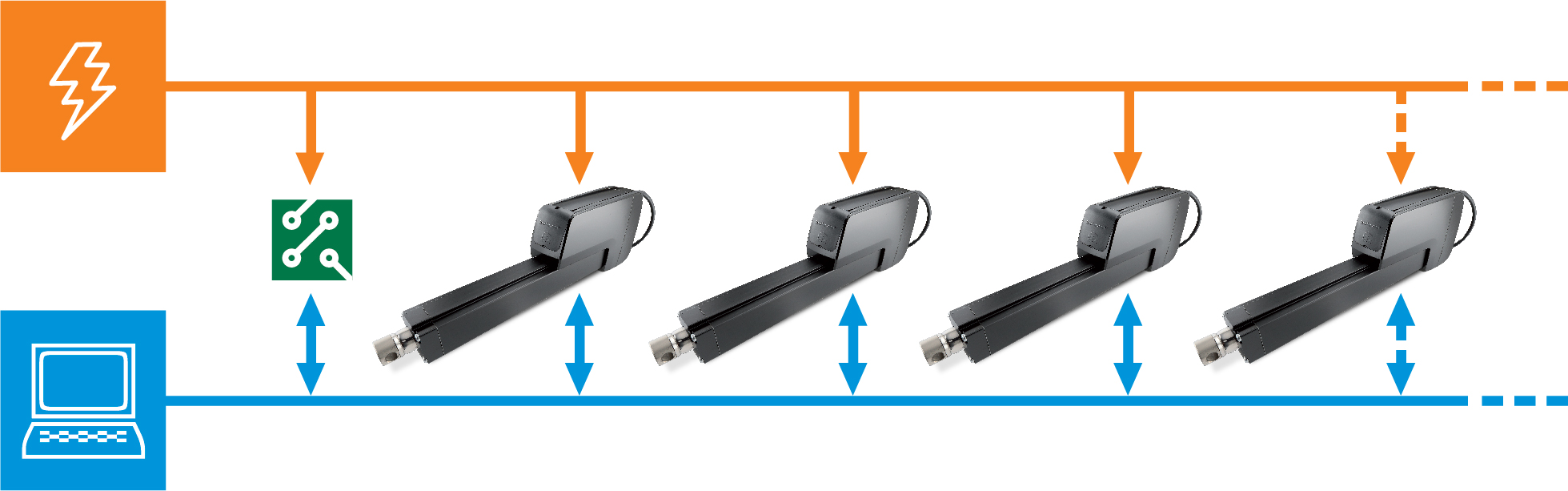

(Image 2) Synchronization, an option with Thomson offered by some manufacturers on smart electromechanical actuators, allows designers to achieve a balanced load for their machines no matter how awkward it may be. (Images of courtesy of Thomson Industries, Inc.)

The smart linear actuator can be easily incorporated into an existing or new system design. For example, synchronization of multiple actuators is easy to program. (Image 2) A popular application for this is the ergonomic raising and lowering of assembly fixtures to fit the operator. The integrated controls simplify the wiring and eliminate the external controls. The master will be controlled by a voltage signal, and the subsidiary actuators will be wired to the master using the onboard electronics. This allows designers to utilize synchronization to achieve a balanced load no matter how awkward it may be. This control feature eliminates bouncing and damage caused to actuators fighting each other trying to move uneven loads. There are also telescoping column actuators where the motor and gearing are inside the column, to deliver a more aesthetically pleasing solution.

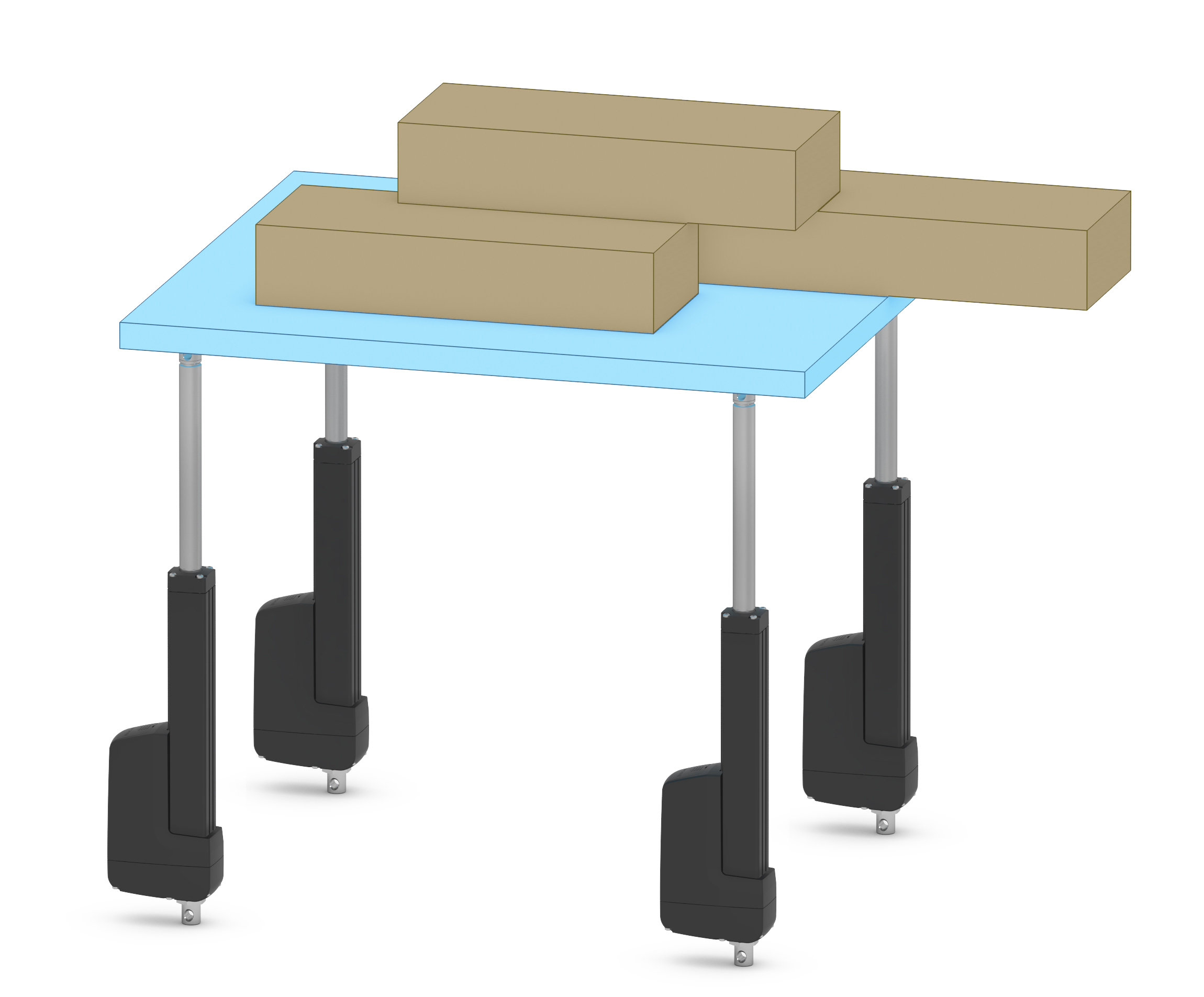

(Image 3) With smart electromechanical actuators, technology and automation allows applications to benefit from condition monitoring. (Image courtesy of Thomson Industries, Inc).

Scheduling predictive maintenance for a smart actuator uses data provided by a condition monitoring feature via the integrated printed circuit board. (Image 3) Monitoring the actuator’s current and temperature will better anticipate its end of life. An increase in temperature could be from overload or from wearing out the actuator components. Current monitoring is both diagnostic and an important safety feature. Current overload will shut down the actuator and protect the machine and the operators. Finally, tracking the number of cycles will also indicate the remaining life of the actuator.

For intermittent duty applications, there is the obvious benefit of easily connecting to a network, but factory workers will also benefit from the lack of leaky and noisy components, and taking comfort in knowing the actuator will stop once power is removed while holding the load.

As factories become smarter and increasingly adopt smart electric linear actuators, they note the difference – realizing greater cost savings as well as a more energy-efficient and easily maintainable environment.

Chad Carlberg, Product Line Manager - Linear Actuators-Americas with Thomson Industries, is responsible for all aspects of the short- and long-term strategies of the linear actuator business, including product road maps and product development. Carlberg earned his Bachelor of Science in Marketing at Butler University and has been with Thomson for 15 years.

Max Miller received a degree in General Engineering from the University of Illinois in 1975 and began his career with Berry Bearing Company in Chicago. He has been with Motion Industries for the past 24 years in various roles including account representative, training instructor, and application engineer specializing in bearings and linear.

For more information, visit MotionIndustries.com/plantservices, or see the MiHow2 video about smart actuators at https://tinyurl.com/y6o7kvve.